Technology and communication will be under the spotlight at the VOLLMER stand at the AMB 2016 in Stuttgart. This is why the grinding and erosion machine specialist will be appearing at the metalworking trade fair under the motto "Dialogue on Precision". This refers not only to discussions with customers and partners, but also to communication between man and machine. From the 160, the 360 is born: The engineering highlight at the AMB will be the latest-generation Vgrind tool grinding machine. VOLLMER will also be showcasing the QXD 250 erosion machine at stand B59 in Hall 8. The Booth will additionally be promoting VOLLMER's range of services, as well as presenting current automation solutions. Also putting in an appearance will be the K850-T automatic saw blade sharpening machine solution developed by Loroch, a VOLLMER subsidiary.

"At the AMB trade fair, we will be presenting our new Vgrind 360 grinding machine. It is one example of how we translate our motto "Dialogue on Precision" to our everyday business," says Dr.-Ing. Stefan Brand, CEO of the VOLLMER Group. "Because this new, improved version came about in part as a result of our own experiences and those of our customers with the previous version, the Vgrind 160."

Vgrind 360 machines on two levels

The response since VOLLMER first launched its Vgrind 160 machine on the tool-grinding market in 2014 has been incredibly positive, leading the company to invest in the machine and further develop it. Right on time for the AMB, VOLLMER has the latest generation ready to go into series production. With greater scope in terms of its travel capabilities, the new Vgrind 360 is able to machine tools up to a diameter of 200 mm, depending on their geometry. Just like the Vgrind 160, the same effective kinematics with two vertical spindles allow for multi-level machining. With its five optimally configured CNC axes, the Vgrind 360 achieves perfect interpolation with short travel distances, affording excellent precision in very little time. The HP 160 pallet magazine, which enables up to 272 workpieces to be supplied, is used at the human-machine interface. The HPR 250 free-arm robot offers three times the previous capacity, and can be configured to automatically produce tools with differing shank diameters.

Technology informed by dialogue

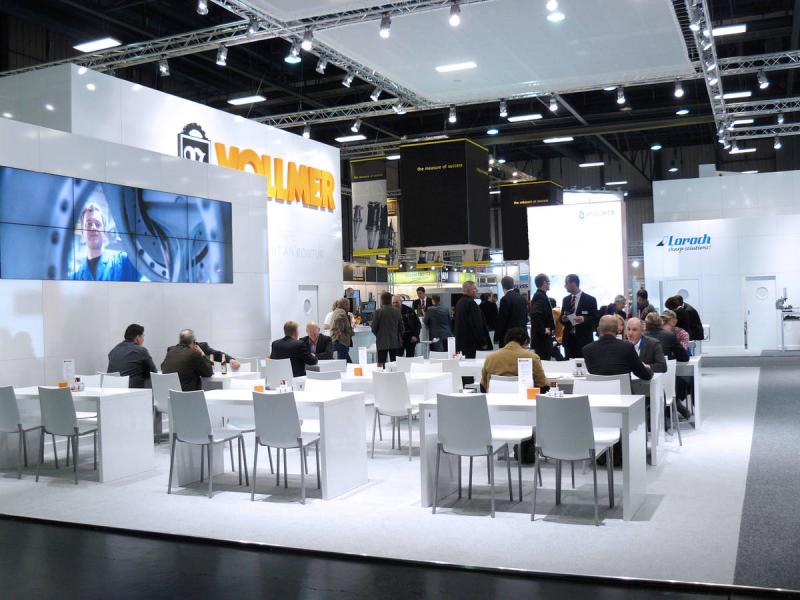

The VOLLMER motto "Dialogue on Precision" refers not only to exchanges with customers, partners and employees, but also to communication at the human-machine interface. The idea behind it is to make both the functionality and automation of sharpening machines more efficient. Furthermore, the Swabian specialist in grinding and erosion machines seeks to tailor the services it offers in relation to training, financing, servicing and maintenance even more precisely to the requirements of its customers. At the AMB in Stuttgart, which is set to take place between 13th and 17th September 2016, VOLLMER will be looking in particular to enter into dialogue with manufacturers of high-quality rotary tools used for machining metals and composites. Besides carbide tools, these are also often PCD-tipped (polycrystalline diamond) tools.

Eroding PCD tools with support bars

The QXD 250 disc erosion machine enables tool manufacturers to sharpen PCD rotary tools such as milling cutters, drill bits and reamers without coming into contact with the workpiece. Visitors to the AMB show will be able to witness the enhanced technological capabilities of the QXD 250, which can also be used to machine PCD support bars on drilling and reaming tools. Support bars stabilise the PCD tool during the machining process, optimising machining quality. The QXD 250 enables the support bars to be chamfered radially and axially, ensuring that they are pre-machined with precision prior to cylindrical grinding. VOLLMER has also expanded the ExLevel PRO programming system in order to considerably improve the functionality and speed of the QXD 250. In conjunction with the ExLevel PRO programming system, the QXD 250 has been equipped with a steady rest to stabilise drilling tools during the sharpening process.

Loroch will present its automatic saw blade sharpening machines

The AMB trade fair exhibit will be completed by the K850-T automatic saw blade sharpening machine solution developed by Loroch, a VOLLMER subsidiary. The machine is designed for the automatic complete machining of metal circular saw blades and for multi-machine operation. Due to its automation level, the K850-T solution allows machine setter and operator to remain separate. In a matter of minutes, all the saw blades that are to be ground can be programmed in – all that remains for the operator to do is to clamp the saw blade in place and press the start button.

Germany

Germany